Greetings, outdoor enthusiasts and curious minds! Have you ever pondered the birth of the dependable outdoor jackets that shield us from the elements? Today, we embark on a journey through the captivating realm of the outdoor jacket manufacturing process. From material selection to the final stitch, this blog unveils the fascinating production journey that transforms raw materials into adventure-ready attire. Let’s delve in and uncover the secrets behind your favorite gear!

Selection of High-Quality Materials

When you slip into your favorite outdoor jacket garment and embark on your next adventure, have you ever wondered what makes it stand up to the elements? It starts with a crucial step in the outdoor jacket manufacturing process: selecting high-quality materials. These materials lay the foundation for a great jacket that performs exceptionally in the wild.

At the heart of this stage is carefully considering fabrics that can handle the demands of the outdoors. Manufacturers opt for a range of durable and weather-resistant materials, each chosen for specific qualities that contribute to the overall performance of the jacket.

Nylon, with its exceptional strength-to-weight ratio, often takes center stage. It’s known for its tear resistance and ability to withstand rough terrains. Polyester, on the other hand, offers excellent water resistance and durability. Blends of these materials provide a synergy of advantages, marrying the best of each fabric’s characteristics.

But it’s not just about the type of material but also its weight, breathability, and texture. Each jacket’s purpose plays a role in material selection. For example, when selecting a hiking jacket, you might choose a lightweight and breathable fabric, while a mountaineering jacket benefits from a more robust and weatherproof material.

As the first step in the outdoor jacket manufacturing process, the selection of materials sets the tone for the entire creation. It’s the foundation upon which the jacket’s durability, weather resistance, and overall quality are built.

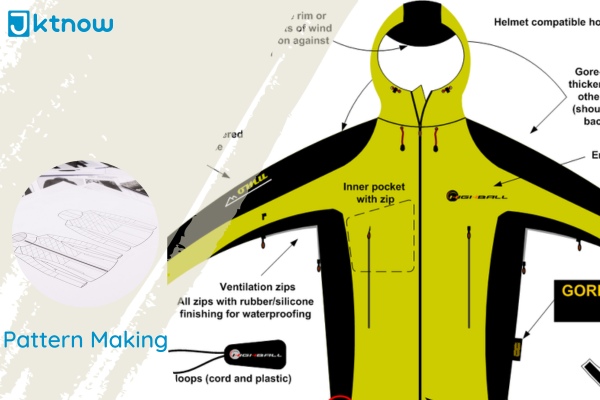

Pattern Making and Design Creation

When crafting outdoor jackets that seamlessly blend style and functionality, the journey starts with a crucial phase: pattern making and design creation. Some styles never make it to consumers. The merchants who choose outdoor clothing in more significant numbers choose the styles they deem best suited for their customers. This is where imagination takes form and design meets technical precision. Skilled artisans and designers collaborate to draft patterns that cater to diverse body types and ensure optimum movement during outdoor pursuits.

Every curve, seam, and angle is meticulously considered for the perfect fit. But it’s not just about fit; it’s also about aesthetics. The chosen design influences the pattern, determining the placement of pockets, zippers, and other elements. Achieving a delicate balance between form and function harnesses creativity, ensuring your jacket keeps you warm, dry, and great-looking.

During pattern making, attention to detail is paramount. From collar heights to sleeve lengths, every aspect contributes to the overall comfort and functionality of the jacket. The process involves a blend of artistry and mathematics, where precise measurements back creativity. Once the pattern is finalized, the blueprint guides the entire manufacturing process.

Pattern-making and design creation are the foundation for exceptional gear in outdoor jacket manufacturing.

Cutting and Preparing the Materials

In crafting outdoor jackets, the stage of cutting and preparing materials is where the blueprint transforms into tangible components. Here, precision is paramount. We meticulously cut each piece of fabric, selecting it for durability and weather resistance according to the pattern.

The skilled worker will cut the fabric and other trims like linings, pocketing, and interlinings as per req.

Seamlessly integrating functional elements such as zippers and pockets, fabric pieces shape aesthetics and utility. This stage marks the transition from raw materials to the tangible canvas that skilled artisans will transform into your perfect attire.

Stitching and Assembly

In the heart of the outdoor jacket manufacturing process lies the intricate stage of stitching and assembly. After passing the cutting section, different parts of the jacket are sent to the sewing section for assembly.

Each stitch is a testament to craftsmanship, ensuring that the jacket not only withstands the elements but also provides comfort and freedom of movement. The artistry lies in creating strong, durable seams that can handle the rigors of outdoor adventures – from rugged trails to snowy slopes.

They integrate functional elements such as zippers, pockets, and ventilation as the jacket takes shape. These details aren’t just about aesthetics and enhancing the jacket’s usability and practicality. The result: a jacket designed not just to look good but to perform flawlessly in diverse outdoor environments.

The stitching and assembly phase isn’t just about joining fabrics; it’s about weaving together functionality, durability, and style.

Weatherproofing and Insulation

When the elements rage, your outdoor jacket becomes your fortress. The manufacturing process is pivotal as we ensure your jacket’s weatherproofing and insulation are top-notch. We meticulously apply weather-resistant coatings and laminates, creating an impenetrable shield against rain and wind. But it’s not just about defense; we understand the delicate balance between warmth and breathability.

Insulation layers are strategically inserted, trapping heat while allowing moisture to escape. Your jacket becomes a microclimate, ensuring you’re comfortable whether you’re trekking through rain-soaked trails or bracing icy winds. In outdoor jacket manufacturing, weatherproofing and insulation are the keys to facing nature’s challenges head-on.

Quality Control and Testing

In the realm of outdoor jacket manufacturing, perfection is the ultimate goal. As we near the culmination of the intricate process, a vital stage emerges: Quality Control and Testing. We rigorously scrutinize every stitch, seam, and detail to ensure each jacket meets the highest durability, functionality, and aesthetic standards. But it doesn’t stop at appearances; functional testing takes center stage.

Jackets undergo a series of trials to evaluate their performance in real-world conditions. Waterproofing, breathability, and overall reliability are put to the test. Only when a jacket emerges triumphant from these assessments can it proudly don the label of adventure-ready attire. This meticulous attention to detail and unwavering commitment to excellence define our dedication to providing outdoor jackets that excel in every aspect.

Customization and Personalization

We understand that every adventure enthusiast is unique. That’s why customization options come into play. Adding logos, embroidery, and personalized touches is all part of the process. Your jacket becomes a canvas for self-expression, reflecting your style and preferences. It’s the small details that make your jacket indeed yours.

With the ability to add logos, embroidery, and unique designs, your jacket becomes more than gear – it becomes an extension of you. Whether you are a bold adventurer seeking vibrant hues or a minimalist explorer preferring subtle details, customization ensures your jacket aligns perfectly with your outdoor identity.

Personalization isn’t just a feature; it’s an opportunity to infuse your story into every stitch. Elevate your outdoor experience with jackets that are uniquely yours. The manufacturing process is more than a sequence of steps; it’s a testament to crafting quality and individuality.

Packaging and Distribution

With the final stitch secured and the last quality check cleared, our meticulously crafted outdoor jackets are ready to embark on their adventure—reaching you. The packaging and distribution phase bridges our manufacturing hub and your doorstep.

Each jacket is carefully inspected one last time to ensure it meets our stringent standards. After approval, we skillfully package it to ensure it arrives in pristine condition, ready to become your trusty companion on countless escapades. From local trails to global destinations, our commitment to excellence shines through every step of outdoor jacket manufacturing.

Conclusion

And there you have it, a glimpse into the captivating world of the outdoor jacket apparel manufacturing process. Every step is a testament to craftsmanship and dedication, from selecting high-quality materials to the final stitch. The next time you zip up your jacket before embarking on an adventure, remember the journey it took to become your trusted companion in the great outdoors.

Get High-Quality Custom Outdoor Jackets From Jktnow!

Our outdoor jackets are not only of good quality but also of novel styles. Consider utilizing our cost-effective outdoor jackets for your sales needs if you’re in the market. What’s more, we don’t stop at manufacturing – we bring your imagination to life by offering custom design, logo incorporation, and material selection services.

All this without breaking the bank, as we believe adventure-ready attire should be accessible to all. Step into the world of quality, customization, and affordability with us. Gear up for your next adventure with jackets that embody the spirit of the outdoors. Connect with us today and be part of the journey.

FAQs

Q1. Are all outdoor jackets made with the same materials?

No, outdoor jackets are made with various materials to cater to different needs. Outdoor jackets commonly use weather-resistant fabrics such as nylon and polyester.

Q2. What’s the purpose of pattern-making in the manufacturing process?

Pattern-making ensures that the jacket fits accurately and comfortably. It’s the foundation of a well-fitting jacket.

Q3. Do all outdoor jackets go through testing before being sold?

Reputable manufacturers conduct various tests to ensure the jackets meet quality and performance standards.

Q4. Can I customize the design of my outdoor jacket?

Absolutely! Many manufacturers offer customization options such as adding logos, embroidery, and unique designs.

Q5. How long does the entire manufacturing process usually take?

The manufacturing process can vary depending on factors such as complexity and volume. On average, it takes several weeks to produce a high-quality outdoor jacket.