Welcome to our insightful guide on the intricate journey that transforms a handful of premium materials into a cozy haven of warmth and style – the custom down jacket manufacturing process. As a down jacket manufacturing expert, I am excited to take you on a detailed tour through the enchanting world of creating these bespoke winter companions.

This comprehensive blog will not only unravel the process step by step but also shed light on why understanding the down jacket manufacturing process is crucial for all enthusiasts and connoisseurs of acceptable winter wear.

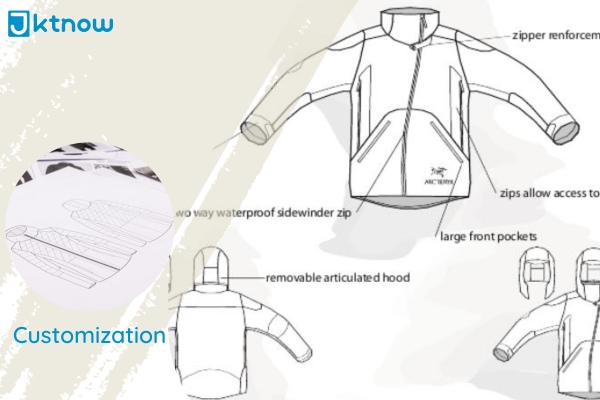

The Essence of Customization

In fashion, customization reigns as a beacon of individuality and self-expression. Custom down jackets have transcended winter wear to become a canvas for personal style. As you craft your custom down jacket, you’re not just selecting a garment but curating an experience.

From the type of down filling to the outer shell fabric, every choice is an opportunity to infuse your distinct preferences. This customization transforms a practical necessity into a statement of warmth and style uniquely yours. The essence of customization lies in creating a winter companion that echoes your personality and wraps you in unparalleled comfort.

Sourcing Quality Materials

At the heart of every exceptional down jacket lies the exceptional quality of the materials used. The journey begins with the meticulous selection of premium down feathers – the essence of warmth and insulation. These down clusters, carefully sourced from ducks or geese, build your custom jacket’s coziness.

The outer shell fabric, equally pivotal, is chosen with precision. Each fabric type brings its unique blend of durability, water resistance, and weight to the ensemble. Nylon and polyester are popular choices, forming the canvas upon which the masterpiece will be woven. To learn more about the specific fabrics used in crafting custom down jackets, check out our detailed article on down jacket fabric.

Cleaning and Preparing Down

The journey of down feathers from field to fashion entails more than meets the eye. The collected data undergoes a thorough cleaning and sterilization process. This is more than a routine cleanse; it’s about crafting hypoallergenic insulation that ensures comfort even for the most sensitive skin.

Following this, the down clusters are fluffed and sorted with finesse. This process ensures optimal loft and insulation potential, turning these clusters into the ultimate warmth providers.

Precision in Pattern Cutting

Once the premium materials are in place, crafting your custom down jacket takes a more tangible form through precision pattern cutting. This phase bridges the gap between design and reality, where the carefully selected shell fabric transforms into the blueprint for your unique winter wear.

Expert pattern cutters meticulously lay out the fabric, ensuring that every piece is positioned to optimize style and functionality. Each cut carries the weight of your chosen design, reflecting the jacket’s length, shape, and features.

Through this intricate process, your jacket’s silhouette emerges, its contours aligned with your personal style preferences. Every detail is considered whether you prefer a streamlined modern look or a more relaxed fit.

Expertise in Sewing Techniques

As we delve into the heart of the custom down jacket manufacturing process, we encounter a crucial phase that requires both skill and precision: expertise in sewing techniques. This isn’t just about stitching; it’s about crafting a jacket that embodies durability, functionality, and style.

Our skilled artisans or advanced industrial sewing machines meticulously sew each fabric piece, ensuring every stitch is in its rightful place. This process forms the foundation of the jacket’s structure, influencing its overall fit and comfort. But it doesn’t stop at mere construction; it extends to the incorporation of baffle construction.

Baffle construction is where technical proficiency meets innovative design. These internal fabric walls prevent the down from shifting within the jacket. Strategically placing these baffles is the key to maintaining uniform insulation, eliminating cold spots, and ensuring you stay warm from every angle.

Filling the Warmth

The heart of a custom down jacket lies in its ability to provide unparalleled warmth without the bulk that often accompanies winter wear. As the meticulously prepared down feathers take center stage, they transform the jacket into a cocoon of comfort. With delicate precision, the cleaned-down clusters are gently filled into the specialized compartments within the jacket’s interior.

The process is akin to artistry, ensuring that each compartment receives an equal share of down, resulting in consistent and efficient insulation. This uniform distribution of down guarantees that every inch of the jacket contributes to keeping you snug and shielded from the biting cold. As you slip into your custom down jacket, you’ll experience the culmination of craftsmanship and warmth that defines the essence of winter elegance.

Sealing in Comfort

In the realm of custom down jacket manufacturing, the process of sealing in comfort goes beyond mere functionality—it’s an art that marries utility with design. This pivotal stage involves the integration of closures that secure the jacket around you and enhance its overall aesthetics.

Zippers, often hailed as the unsung outerwear heroes, effortlessly merge convenience and style. Customizable zippers allow you to curate a jacket that aligns with your minimalist or bold taste. On the other hand, Snaps offers a classic touch, combining ease of use with a timeless look.

Your choices during this stage are vital to the jacket’s wearability. They determine how snugly the jacket fits, how effectively warmth is retained, and how you project your style to the world.

Quality Control and Assurance

Craftsmanship is our guiding principle, and quality is our unwavering commitment. The culmination of the custom down jacket manufacturing process lies in the meticulous quality control and assurance stage. Our expert team scrutinizes every stitch, seam, and detail to ensure your bespoke jacket meets the highest standards. If any irregularity is discovered, feedback to the relevant stage of the production line and, if necessary, a factory-wide adjustment is set in motion.

Our skilled inspectors meticulously examine each jacket, checking for stitching precision, filling distribution, and overall workmanship. Any imperfections are rectified precisely, affirming that the final product surpasses expectations. This stringent quality control guarantees that your custom down jacket provides exceptional warmth and is a testament to enduring craftsmanship. Our dedication to quality control and assurance sets us apart in a world where mass production often prevails.

Showcasing Ethical Practices

A deep commitment to ethical practices lies at the heart of our custom down jacket manufacturing process. We understand the responsibility of creating products sourced from nature’s bounty. We root our approach in sustainable sourcing, actively ensuring that we procure down feathers for our jackets responsibly, without harming the environment or the creatures that provide these precious materials.

Moreover, our dedication extends to the human hands that bring these jackets to life. We ensure fair labor practices, treating every individual involved in the manufacturing process respectfully and providing fair compensation for their craftsmanship. This is reflected in the quality of our jackets and the positive impact we leave on communities.

By showcasing these ethical practices, we aim to provide you with a premium custom down jacket and give you the confidence that your choice aligns with sustainability and social responsibility values. Your custom jacket becomes more than just a piece of clothing; it symbolizes conscious consumption and thoughtful fashion.

Conclusion

In conclusion, the custom down jacket manufacturing process is a symphony of artistry, precision, and warmth. It’s not merely the transformation of materials; it’s creating a winter identity that resonates with your unique style and preferences. Every stitch, every feather, and every choice culminate in a masterpiece that is uniquely yours.

Get a High-Quality Custom Down Jacket From Jktnow!

Ready to embark on the journey of creating your own custom down jacket? Explore our options, from down types to shell fabrics, and design a winter companion that speaks volumes about you. Embrace the warmth and style that only a custom down jacket can provide.

FAQs

As a famous down jacket manufacturer in China, we know you will have many questions. Here, we answer your questions with precise expertise.

Whether you are curious about our capabilities or seek detailed information about our quality standards, our FAQ section aims to provide you with the required knowledge.

Q1. How do I choose the shell fabric for my custom down jacket?

We offer various shell fabric options, each with unique attributes. Consider durability, water resistance, and weight to select the fabric that best fits your preferences.

Q2. What is baffle construction, and how does it enhance the performance of my jacket?

Baffle construction involves creating internal walls within the jacket to prevent down migration and cold spots. This ensures that the insulation remains evenly distributed, optimizing warmth.

Q3. Can I customize the closures on my custom down jacket?

Absolutely! Our customization options extend to closures as well. You can select zippers, snaps, and other closures that resonate with your style and functional needs.

Q4. How do you ensure ethical practices in your manufacturing process?

We prioritize ethically sourcing materials, including down feathers, and uphold fair labor practices. Our commitment to sustainability and responsible production is embedded in every process step.

Q5. What makes a custom down jacket a worthy investment?

A custom down jacket offers unmatched comfort, style, and individuality. It’s not just a winter garment; it reflects your personality and preferences, ensuring you stay warm while making a statement.